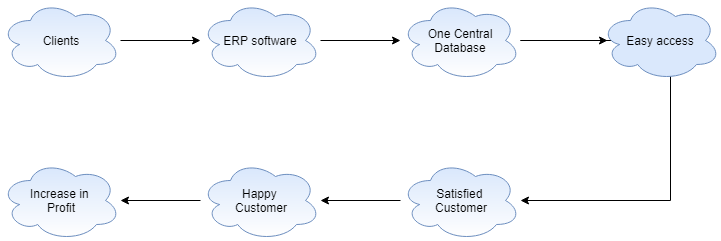

An OSMTM software integrates all the functions in the manufacturing industry and every business function relies on a single database.

- Inventory and material

- Production

- Sales

- Accounting

- Human Resource

Why Should You Upgrade to OSMTM?

Here are the advantages of why you should upgrade to Operating system for manufacturing:-

- Streamlining Processes

As manufacturing industries are growing their operations are becoming complex, Operating system for manufacturing automates all the operations going on in a manufacturing industry and helps to manage real-time information. This software helps to increase productivity and efficiency as it prevents duplicacy of data and helps in improving orders on-time.

- Reductions in cost

The administrative and operation costs are reduced when you deal with real-time information. It helps in quick decision making.

- Flexibility

Modern OSMTM is robust, flexible and easily configurable. OSMTM has the capability to adapt to changing and unique needs of the business.

- Competition

In this world of growing competition every business entity wants to be at the top and are investing in OSMTM and have started taking its benefits.

Perks of using OSMTM suites at a glance:

• Curbs manufacturing cost

• It helps to boost resource utilization

• Reduce manufacturing bottlenecks

• Inventory is improved

• Improves customer service

• Enable accurate and faster revenue tracking

• Boost profitability

• Generates code faster

• Gains real-time visibility

Supply and demand both can be managed by OSMTM. So we can also manage sales similarly by our OSMTM software as well as the purchase orders. By an OSMTM system one can approve or decline purchases. OSMTM is a managing tool that enables unmarked transactions and production. OSMTM is generally available as an On-Premise installation or in SaaS model.

OSMTM i.e. Enterprise Resource Planning is a business management software that manages all the processes of the business. OSMTM helps to integrate different processes in the business. G.A.P OSMTM manages the operations like no one else.

Unique Features of G.A.P-OSMTM are:-

- Online Inspection

- GANTT Chart for tool handling in manufacturing industry

- Handling of GSTR-1 and GSTR-2

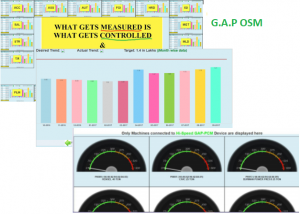

- Real-time data of the IOts is available through G.A.P OSMTM.

- Monthly MRP calculated on a single click.

OSMTM is AWESOME. It is much more extensive than an ERP. It includes all the basic modules of a common OSMTM but is designed to DIGITIZE your work environment. It also creates and works using IOTs for real-time online controls.

G.A.P OSMTM helps the Industry to meet the existing and future challenges:

• Reduces Time to Market ( Better controls on Design, Development, Production and Right First Time)

• Enhances Flexibility ( Fast Change Management / Response to changing Customer needs )

• Improving Quality ( of Products, Services, Communication and almost everything that you do )

• Increasing Efficiency ( of Men, Machines and Money )

• Reduction in Cost ( for making you competitive and more Profitable )

And all this in a simple user friendly way that is easy to own, install, implement and control.Suitable for both Big and Small Businesses. It is available both on the cloud as a SAAS model or a full On-Site installation.It is Browser based and accessible from anywhere and using any device ( PC, Laptop,

Tablet or Smart Phone ). It has configurable security setup for ensuring data safety.

All the data that is reflected in the software is accurate and cannot be changed or manipulated from the front-end all the data is protected on the server and there is no risk of loss of data as there are multiple backups from where data can be retrieved.

With the help of OSMTM software there will be continuous flow of information between various departments. There will be no loss of communication and no miss communication between the employers and the employees. The unique features of G.A.POSM are as follows:-

- This is specially designed for the manufacturing industry and handles all the processes related to a manufacturing industry.

- All the processes like order management, product management, asset management, sales management etc. are managed through OSMTM.

- The employers are satisfied as the employees are happy and give their full potential at work their efficiency is increased which leads to increase in profit and decrease in revenue which makes the company lead in the growing competition.

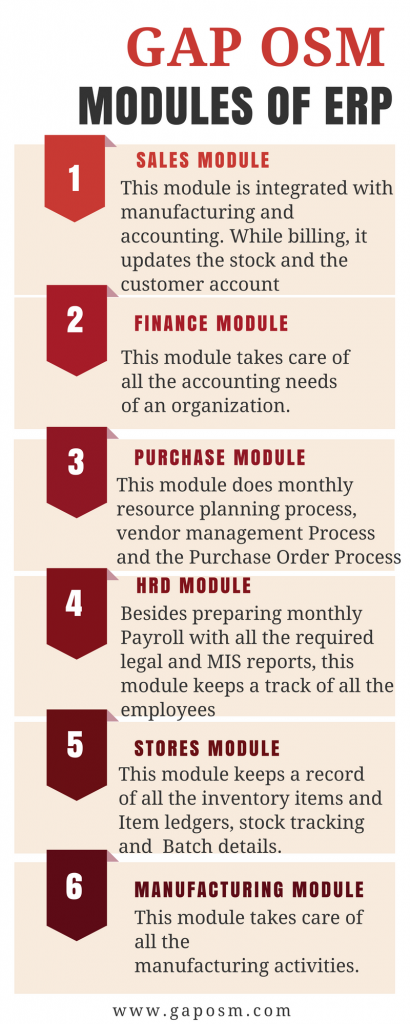

OSMTM system definition: OSMTM system is defined as the software which helps to manage all the activities going on in the business. OSMTM system helps to remove all the redundancies involved in the business and once an OSMTM software is integrated and implemented in the business it becomes the lifeline of one’s business as all the transactions are done through the software. GAP OSMTM streamlines all the processes in the industry and helps to manage these processes in a systematic manner. GAP offers different modules which manages the different departments in your organisation.

OSMTM system definition: OSMTM system is defined as the software which helps to manage all the activities going on in the business. OSMTM system helps to remove all the redundancies involved in the business and once an OSMTM software is integrated and implemented in the business it becomes the lifeline of one’s business as all the transactions are done through the software. GAP OSMTM streamlines all the processes in the industry and helps to manage these processes in a systematic manner. GAP offers different modules which manages the different departments in your organisation.