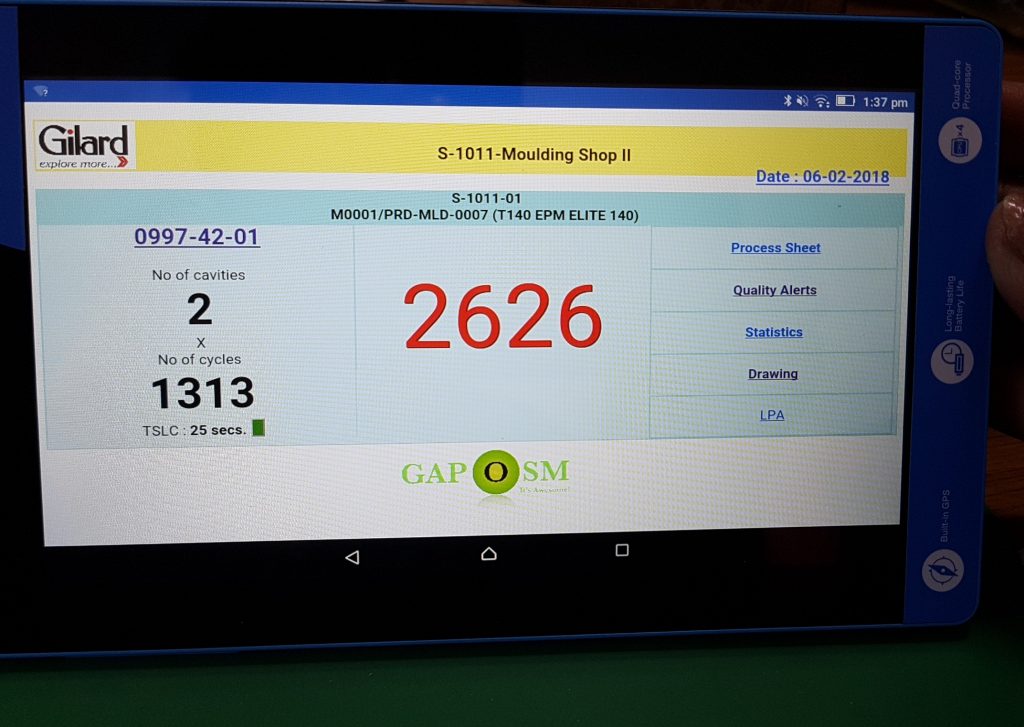

With the machine monitoring system available in the industry you can use the data for variety of things inside or outside the industry that has been collected automatically. Here are some examples of Industry 4.0 that can be used outside the industry are –

Material Shipment to customer – The customer comes to know exactly how many parts have been produced at any given time and what is the expected date of delivery of the work order.

Material ordering from vendor – The software automatically mails the vendor about the order for raw material, the machine monitoring system tracks the production from the machine. The software updates the data about the availability of raw material, which automatically mails the vendor about the order when the reorder quantity is reached.

Part traceability – Part traceability can also be included in production monitoring system, that can be done on the vendors part who marks each part with a unique serial number carved on its bar code. The serial number of each part is recorded in the software. Suppose if any part is rejected due to raw material defect, its serial number is recorded from the software and we can get the serial number of the parts which are made in the same batch and are checked for the same defect. With which you can track down and replace all parts of the same batch. The vendor also uses this data to fix the issue.

Logistics – The software which is talking to monitoring device can track the location of the truck which is doing shipment of incoming raw material. With the tracking one can know the delays in delivery due to breakdown, traffic jam or accident. The software then estimate the time of arrival of the raw material, and plan the production accordingly. Your customer’s has also access to the same data and they can use this data to know if their order is ready, where it has reached and when it will arrive their destination.

Maintenance – When a machine breaks down, the monitoring system can send email and SMS alert to the person concerned. One can control the spares parts inventory by automatically ordering spare parts for preventive maintenance, based on the condition.

Industry 4.0 components

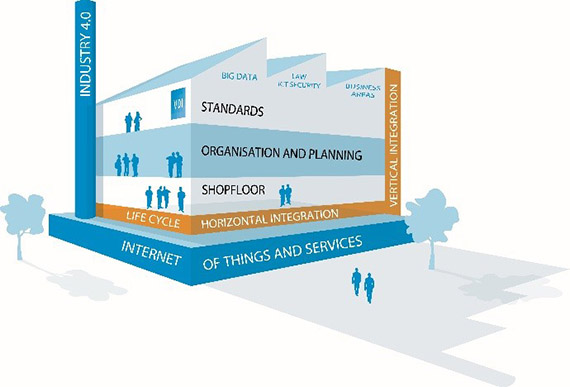

Industry 4.0 comprises of cyber-physical systems i.e. CPS these are machines which is connected to a computer that is connected to the internet. The machine can be any tool cutting, making textiles, food processing etc. Cyber means related to computers, the computer is an embedded system that controls and monitors the machine. The inputs and outputs are connected to electronics on the machine and its ability to send data to the computer.

Now what is IOT for Industry 4.0 it stands for Internet of Things and Internet is the same old one which we have been using for years but now it has been used by not only people but also things. The things that are included in IOTs are PCMD, attendance machines, manufacturing machines, robots, G.A.P POMS etc.

Cloud computing in Industry 4.0 : This is done by using a network of servers hosted on the internet that stores, manages and processes data, instead of a local server. A server is powerful, reliable and more has large storage space than a normal PC.

Now the working- The sensor gets the data from the machine and sends this data to the cloud server over the internet. The software takes the data and commands the machine according to that data whether to slow down, stop or speed up, reorders material and do other things. A small size industry can also implement Industry 4.0 to go into digitization. There is no constrain for any industry whether it is small, medium or large they can implement Industry 4.0. Digitization helps to automize the work processes in the industry. All the data is made available in real-time and can not be tempered with.